Metrology options

Metrology and add-on inspection options

Metrology

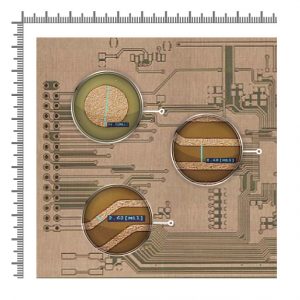

2D Metrology

2D Metrology: +2CD/+2DM

2D metrology enable accurate two-dimensional measurements of individual elements of a PCB circuit. CIMS offers two types of 2D metrology: +2CD and +2DM.

+2CD: real time micro-measurements of individual PCB elements, such as traces or pads, with up to ±3~5 microns accuracy (subject to surface condition).

+2DM: AOI integrated macro-measurements of an entire panel in order to determine any dimensions violation.

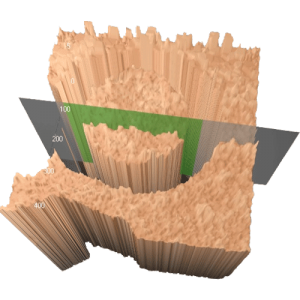

3D Metrology

3D Metrology: +3DH/+3DP

3D metrology enable accurate three-dimensional measurements of individual elements of a PCB circuit. CIMS offers two types of 3D metrology: +3DH and +3DP.

+3DH: real time 3D-measurements of a height or depth of individual PCB elements achieving up to ±2~3 microns accuracy (subject to surface condition of a measured element).

+3DP: real time 3D profiling of individual PCB elements with up to ±1~2 microns accuracy (subject to surface condition of a measured element).

Special Applications

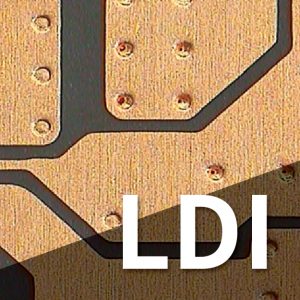

Laser drill scanning add-on

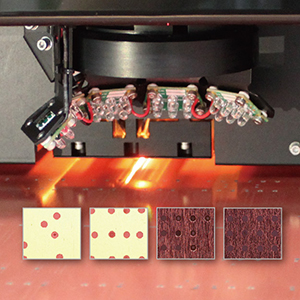

LDI: Laser Drill Inspection

CIMS LDI is a laser drill inspection option designed for HDI PCB and IC Substrates. It is supplied as an add-on option suitable for all CIMS Phoenix family AOI models capable of inspecting laser drills of all sizes (subject to base system’s resolution).

AOI systems equipped with LDI are capable of scanning both pre- and post-plating laser vias as well as conformal masks. Each such application features its own dedicated user interface making a job setup intuitive and straight forward.

Final inspection add-on

Fi: Final Inspection

Fi (Final Inspection) option allows inspecting of finished boards with CIMS AOI. It is supplied as an add-on option suitable for all CIMS Phoenix family AOI models extending their capabilities to final inspection.

Fi can reliably detect common defects on gold, copper and solder mask.

Systems equipped with Fi option feature a dedicated final inspection interface for parameters setup.

PVH – Plugged Via Holes Inspection

PVH: Plugged Via Holes Inspection

PVH option is an add-on functionality for selected CIMS AOI models enabling inspection of plugged via holes down to 75 microns in diameter. This new system further extends CIMS line of products an options for drill inspection applications.

PVH option is the perfect solution for customers who are looking for reliable and accurate tool to control the depth of resin within each drill with sufficiently fast throughput to match high volume production.