Digital Solutions

Digital Solutions

PCB Inspection engine

Spark™

Spark is the platforms that runs CIMS inspection engine that powers our latest generation of automated optical inspection systems. Spark 3.0 is the latest generation of this platform which combines both hardware and software modules. Some of the key features of Spark technology include the following:

- Advanced image processing algorithms enable customized detection that ensures optimal performance for all combinations of PCB designs and surface conditions;

- Multizone is the Spark’s way to analyze and group different parts of a circuit in order to independently optimize inspection performance for each zone element;

- Multistep provides an additional level of inspection flexibility with independent settings for each PCB step;

- Advanced false calls filtering mechanism filters out false calls by analyzing CAD data prior to the actual scanning thus dramatically reducing setup time on AOI;

- DST (dual space threshold) is a special image processing method to increase AOI sensitivity for fine shorts while keeping false calls rate to an absolute minimum.

Sprint™

Sprint is software platform that powers CIMS VVR – the latest generation verification solutions that combine both virtual and physical verification in one system.

VVR systems that run on Sprint platform are able to automatically sync their settings and exchange data through CDBIC server allowing for seamless and secure operation.

Sprint allows smooth integration of verification data within the large context of smart factory allowing quick and easy access for the purposes of QA analysis.

Verification platform

Semi Inspection engine

Blaze™

Blaze is CIMS latest detection that is in the heart of Semiconductor inspection powering our latest inspection solutions for Packaging and Microelectronics segments.

Blaze™ unique capabilities enable highly reliable inspection of wide range of advanced Microelectronics products, full data integration with other processes and compatibility with various advanced data exchange protocols that are common in Semiconductor industry.

CIMS AI

CIMS has developed dedicated AI solutions that can offer direct benefit to our customers by accurately categorizing verification results and greatly reducing loading on the human operators.

Various AI-based options developed by CIMS consist of customized models which are optmized for a specific product type and/or designed to deliver a pre-defined level of performance.

CIMS AI solutions are typically deployed at the verification stage of AOI cycle and can handle wide range of both grey level, color and video images.

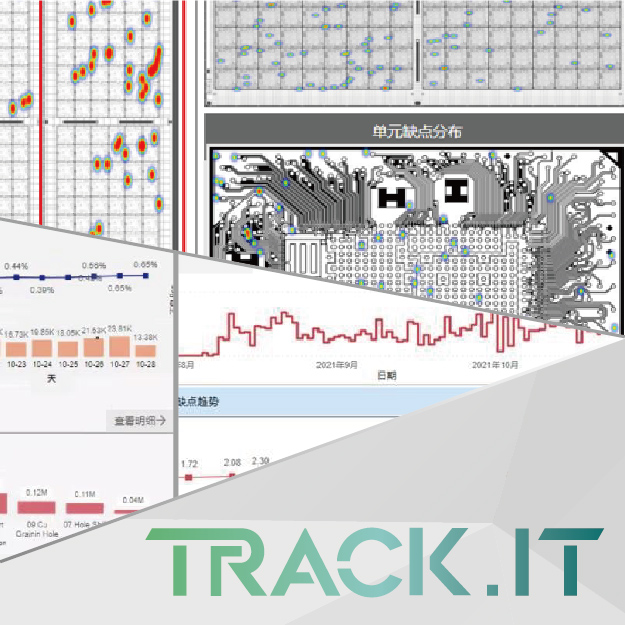

Track.It™

Track.It™ is a dedicated yield improvement and quality control solution that pulls in related yield and defect data from multiple inspection processes into big data database and performs big data computing and analysis. Such processes include all the types of CIMS native inspection solutions as well as third party suppliers allowing for the most comprehensive overall quality picture.

Big data computing and management by Track.it™ enables our customers to detect and analyze quality issues in real time and take prompt corrective and preventive actions involving various production stages.

CDBIC/CDB SDK

CDB and CDBIC are data management systems integrated with CIMS equipment. They are designed for quality and process control of the entire PCB inspection production cycle while also serving as real time defects classification system. CDBIC adds another layer of control by tracing individual defective units across multiple layers and processes. It also integrates AVI data into the data management process combining it with the inputs from AOI.

CIMS SDK (software development kit) enables third party suppliers to have a secure and reliable access of the quality-related data collected during inspection process in order to integrate it with other tools in the context of smart factory as well as link it with various factory-wide MES and ERP software.

Defects classification and scrapped units mapping

Virtual Verification System

VVS – Virtual Verfication Station

VVS consists of a server that pulls the images of defects from every CIMS AOI and then sends them to VVS stations for sorting and filtering. In VVS stations, those images are shown to operators who then quickly remove non-critical and non-functional calls while passing only images that are most likely to represent true defects directly to CIMS verification solutions (VVR & CVR). As a result, subsequent visual verification of actual panels with CIMS VVR/CVR focuses mostly on marking and repairing of the real defects rather than skipping over non-critical and non-functional defects.

VVS can also be combined with CIMS AI verification solution enabling our customer to further enhance the efficiency and productivity of the entire AOI and AVI inspection cycles.