Description

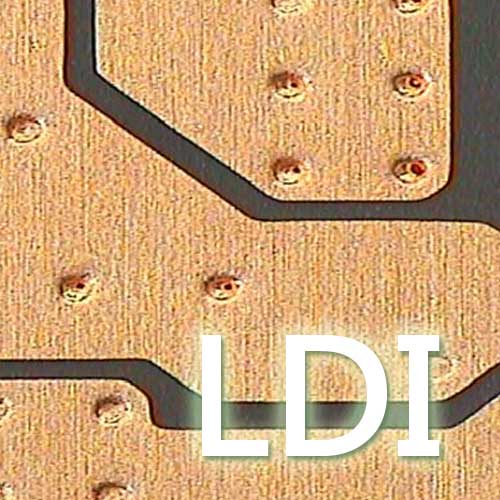

CIMS LDI is a laser drill inspection option designed for HDI PCB and IC Substrates. It is supplied as an add-on option suitable for all CIMS Phoenix family AOI models capable of inspecting laser drills of all sizes (subject to base system’s resolution).

LDI option works with both Microlight™ and Prisma™ illumination technologies utilizing special algorithms and logic optimized for detection of defects that typically occur in laser drills (laser vias). AOI systems equipped with LDI are capable of scanning both pre- and post-plating laser vias as well as conformal masks. Each such application features its own dedicated user interface making a job setup intuitive and straight forward.

LDI option adds a new level of versatility to Phoenix AOI systems enhancing their inspection capabilities to more applications and PCB manufacturing process stages.

Highlights

- Integration with CIMS AOI systems

- Combines laser via inspection with regular inspection

- Supports both sampling and 100% inspection

- Dedicated user interface for different laser drill types

- Suitable for all sizes of laser drills

- Easy and intuitive setup

Options

- Can be combined with +3DP metrology for LV profiling

- CDB/CDBIC connectivity – defects classification and virtual defects mapping

- VVS connectivity – virtual verification system