Description

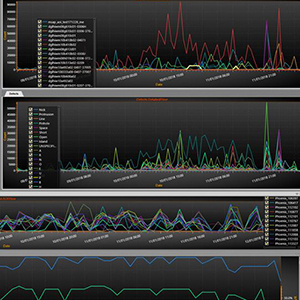

CQC, which stands for CIMS Quality Center, is the live quality monitoring tool that allows users to have an up-to-the-minute view of ongoing quality-related issues based on data generated by AOI in real time.

How does CQC work?

CQC is a software that runs on a stand alone standard computer that must be linked to CDBIC server in order to retrieve data from AOI and CVR systems. The display options are very flexible in order to accommodate various types of users and preferences.

For example, a QA manager may be interested in defects distribution statistics and trends, current yield, defects maps and clustering of specific types of defects on a panel. On the other hand, a production manager may choose to focus on equipment utilization data or total panels scanned and verified. An AOI supervisor can configure a view that shows current equipment status, average total calls trends or each individual throughput data.

All those different views and preferences can be easily configured per user with practically unlimited customization options making CQC an invaluable tool for every level of PCB manufacturing operation.

Highlights

- Real time quality data control

- Consolidated view of inspection data

- Configurable setup for different users

- All critical data in one view

- CQC info can be shown on individual monitors or single large display

Options

- VVS connectivity

- CDB/CDBIC connectivity

- Compatibility with older AOI models